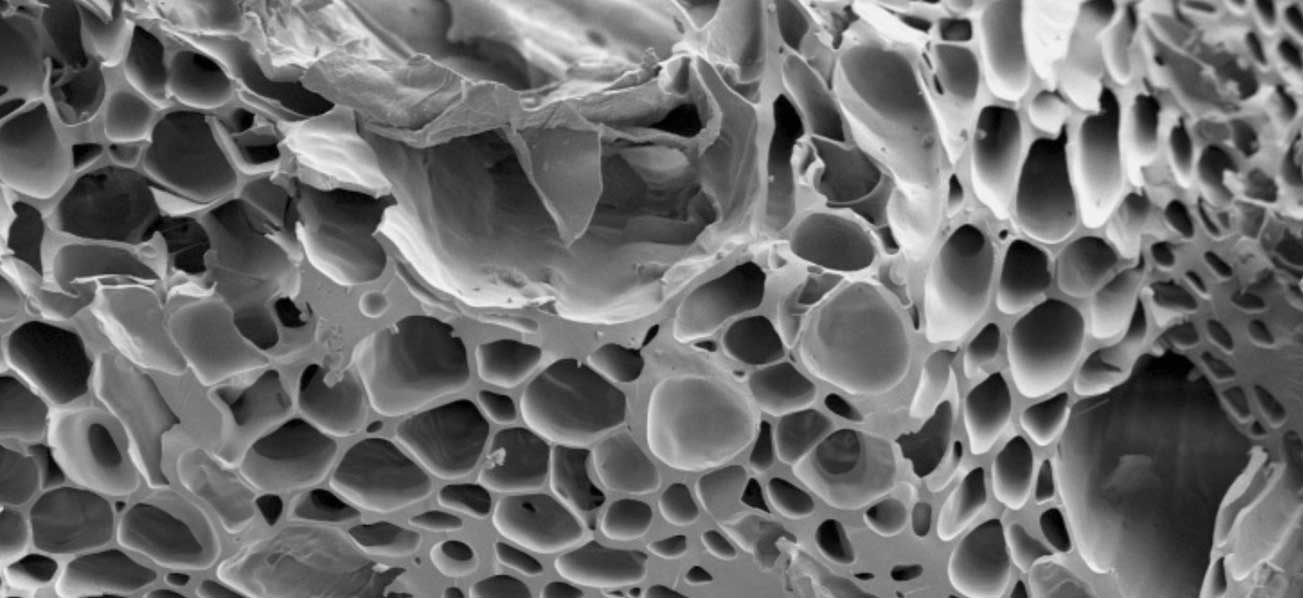

Activated Carbon is considered the raw form of graphite. However, unlike graphite structure, it has a random defective structure with its macro and micro pores. The graphite structure gives a very large surface area to Activated Carbon. 3 grams of Activated Carbon may have the surface area of a football field. Activated Carbon has the strongest physical adsorption power. The surface area of the Activated Carbon ranges from 500 m2/g to 2000 m2/g.

Surface Area:

The surface area of the Activated Carbon ranges from 500 m2/g to 2000 m2/g. In other words, 3 grams of Activated Carbon may have the surface area of a football field. The surface area of the carbonaceous materials can be expanded by the activation process.

Total Pore Volume (TPV):

TPV states the total volume of pores in an Activated Carbon. The activity of Activated Carbon increases as the total pore volume increases and it is expressed in mL/g.

Pore Volume Distribution:

The property of the Activated Carbon is measured by the distribution of pore size. Decolorization applications require Activated Carbon with high dispersion mesopores.

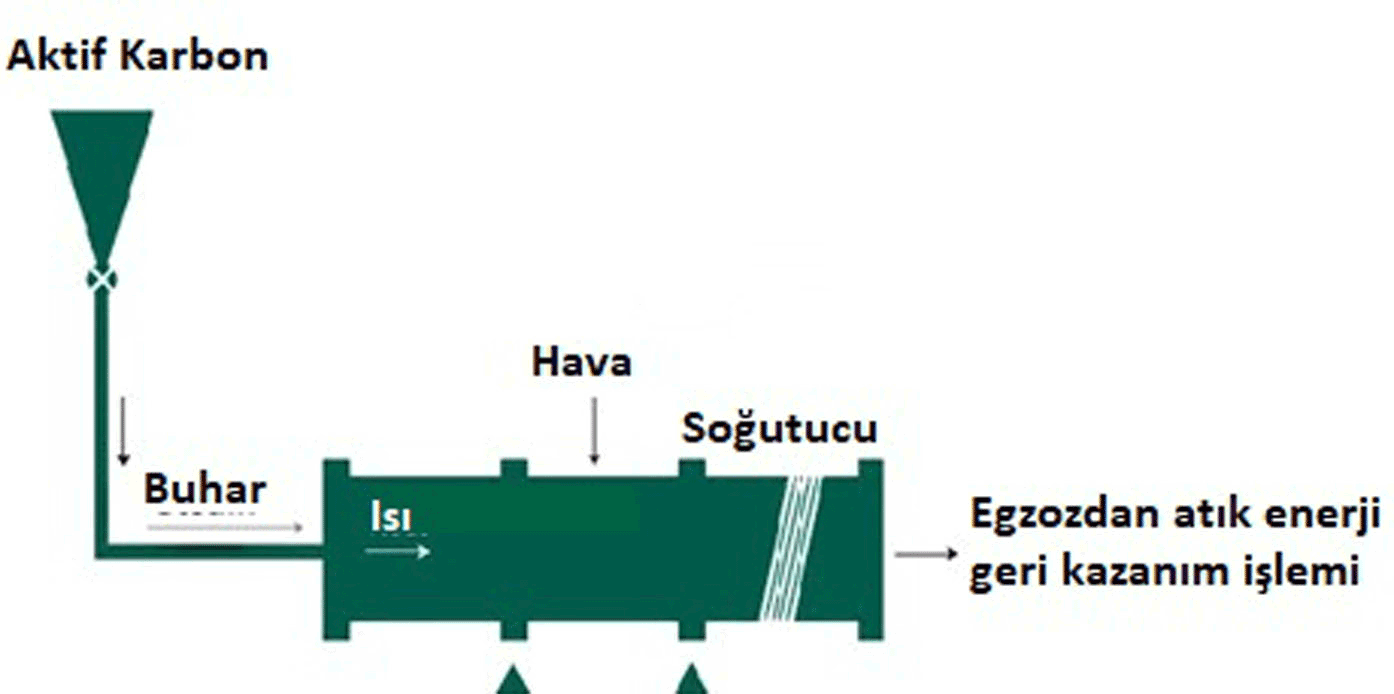

Activated Carbon is a solid material with a porous surface that can combine with different molecular structures. The interaction of Activated Carbon can be only physical (either by interaction between non-bonded atoms or interaction of Van der Waals forces) or by its physical-chemical structure, and its strength can vary depending on the type of molecule and the type of Activated Carbon. Activated Carbon generally produced by steam activation process. In this process, carbon or carbon-containing starting materials are subjected to gasification by reacting with steam or other oxidizing materials. Raw materials such as wood charcoal, hard coal, lignite, coconut-based coal, swamp coal or wood-based coal are used. In addition, cellulose-based raw materials can be used in the chemical activation process to activate raw materials.

The effectiveness of Activated Carbon depends on the inner surface area. As the inner surface area increases, the efficiency increases. The normal surface area of Activated Carbon ranges from 500 m2/g to 1750 m2/g.

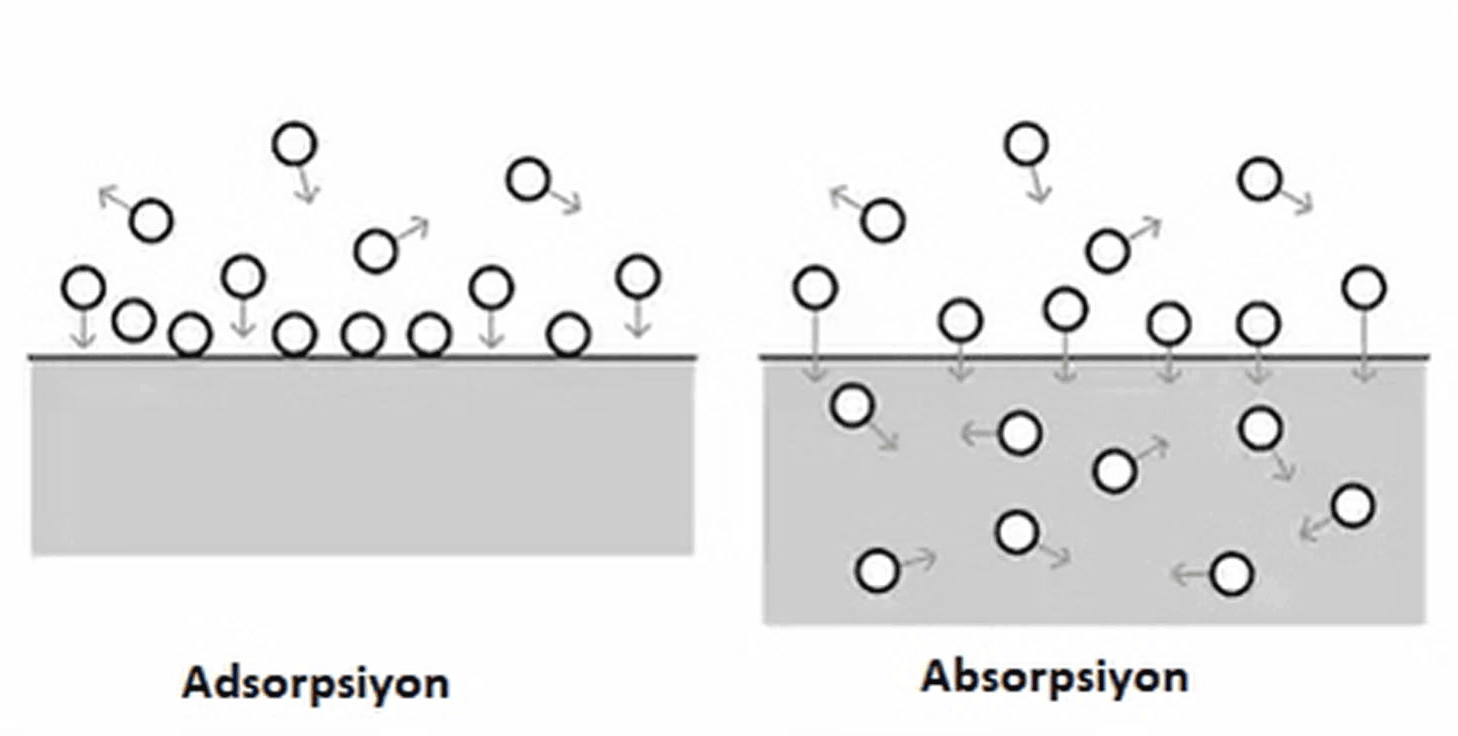

Adsorption is the attachment of molecules of a substance to the surface of activated carbon. Activated carbon is characterized by high micro and macro-pores that allow adsorption of the adsorbate to the inner surface. There are two kinds of adsorption.

Physical Adsorption:

Physical adsorption occurs when the material to be adsorbed is attached to the inner surface of the activated carbon by the Van der Waals force between molecules. The gravitational force decreases as the distance between the pore wall and the molecule increases.

Chemical Adsorption:

It occurs by a strong bond between the adsorbate molecules and the chemical complexes impregnated with the activated carbon into the pore wall.

Activated carbon is generally used to adsorb organic materials. Also, inorganic materials having certain heavy molecular weights, such as iodine and mercury, can be adsorbed.

Adsorption capacity of activated carbon increases;

- a) As the molecular weight increases

- b) As the number of functional groups increases

- c) As the polarity increases.

Granular Activated Carbon is the milled and sieved form of Activated Carbon of irregular shape. Granular Activated Carbon is used to purify high volumes of gas or liquid. Granular Activated Carbon is harder and longer lasting then Powdered Activated Carbon. Can be reactivated several times.

Powdered Activated Carbon is generally used in liquid phase or flue gas applications. The particle distribution of the Powder Activated Carbon generally ranges from 5 to 150 micrometers. It can be used in batch or continuous processes. Powdered Activated Carbon cannot be reactivated or reused as Granular Activated Carbon.

- Resistance to abrasion

- Adsorption capacity

- Particle size distribution for optimum flow

- Adsorption and desorption rate

- Product suitability for use

- Some substances that may be effective or may interfere with the loading of carbon

- Different raw materials

- State and size of raw material

- Activation feed rate

- Activation temperature and pressure

- Oxygen content during activation

- The final product mixture

TechCarb serves the sector with product options in different specifications, shapes and sizes (granular, extruded or powdered) to meet the needs in many areas of use.